Three key reasons M12 connectors are the smart choice for Industry 4.0.

Though M12 connectors were available decades before the IIoT was even a concept, they have become the preferred connector for industrial Ethernet. For data transmission, they are used on the device side – pulling data from devices and transmitting it to the application where data is aggregated to provide useful information to the user. They make the connections between the PLC, sensors, and the I/O blocks, as well as to wireless access points. M12 connectors are also used to transmit high levels of power supplies for extended time periods in applications such as AC motors and drives, motor control switches, and low-voltage applications like fieldbus Ethernet components and network devices.

1. Unrivaled ruggedness

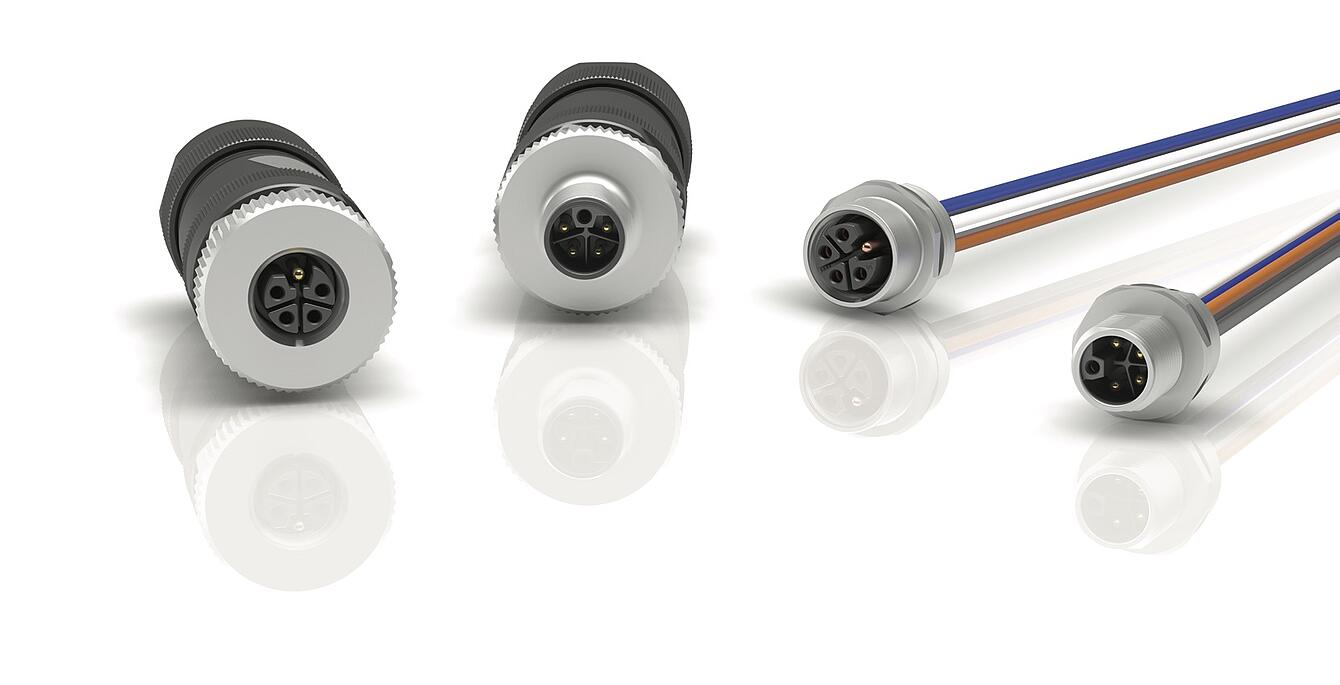

Compared to the RJ45, the other most commonly used industrial connector, M12 connectors offer superior performance in harsh conditions. The circular design shields contacts from contaminants such as dust, moisture, heat, and foreign objects. M12 connectors offer a minimum of IP67-rated ingress protection against dust and water, while also protecting against impact, vibration, UV exposure, and temperature changes. For the most demanding applications, such as those requiring frequent washdowns, they are available with IP68 and IP69K ratings.

Mating cycle ratings are also an important consideration for machine builders choosing a connector for their application. A connector’s mating cycle rating is determined by the material used for contacts and plating, as well as the thickness of the plating. Cheaper connectors, made for example with tin plating and copper alloy contacts, will not perform as well as those made with corrosion-resistant materials such as thick gold plating and beryllium copper contacts, which are typically rated for >100 mating cycles.

2. EMI shielding

Hard-wired connections offer some advantages over wireless connections, including the intrinsic security of physical connections and the avoidance wireless interference. This is especially important because the new IIoT enabled factory is often filled with electromagnetic interference (EMI), also called radio frequency interference (RFI). Unseen and unheard by people, this electronic noise pollution frequently interferes with high-precision sensors already taxed by the physical noise and vibrations of a busy factory floor.

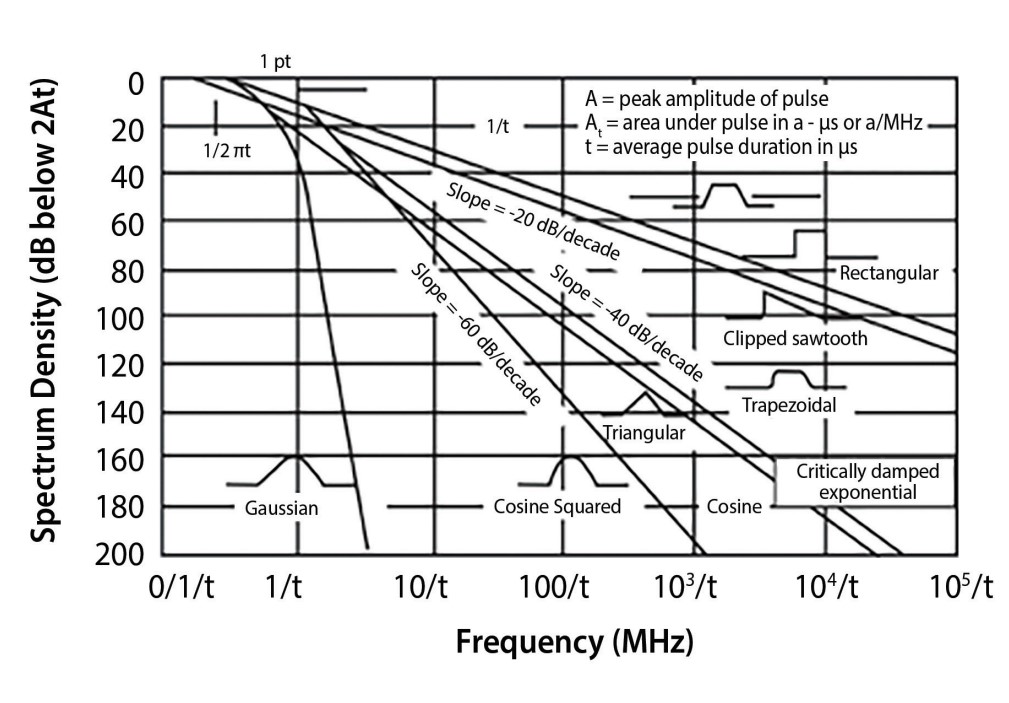

“The faster the digital speeds, the greater the required circuit bandwidth, and the more difficult it is to control both radiated emissions and susceptibility” (Fenical). As illustrated on the graph on the right, EMI increases with the speed of data transmission. The increasing pervasiveness of EMI places an additional burden on manufacturers to design equipment that both generates as little EMI as possible, and ensure that their equipment has reasonable resistance against EMI so that operation isn’t affected where it is a factor.

In order to satisfy these requirements, manufacturers need connectors and connecting cables with sufficient shielding properties. Connectors must have conductive (metal) housings to which the cable shield can be terminated. In the case of cylindrical connectors, the cable shield has to be carefully connected to the connector to provide 360° shielding. Generally, good shielding performance is achieved when the braided shielding of the cable is firmly connected to the conductive connector housing. (Plastic connectors without metal sleeves have no possibility to terminate to the cable shield.)

In addition, it is important that the mated connector pair has a secure galvanic connection between the plug and receptacle housing. It is also necessary that the panel mounted receptacle has a good galvanic connection between the metal receptacle housing and the metal panel surface. The shielding attenuation is measured in decibels (dB) and is frequency dependent. Good shielding provides high attenuation values over a large frequency range (MHz).

3. Compact size

The Industry 4.0 trend towards miniaturization requires more compact components and connectivity solutions, even as power and data transmission needs grow. Increasingly smaller devices and sensors are transmitting more data, which requires more connection points, which means that connectors have to deliver the same (or more) power density in a smaller footprint.

Originally designed to reduce the size of the 7/8” connector, which was standard at the time for sensors, the M12 connector has an outside diameter locking thread of just 12mm. Its small footprint makes it well suited for applications with little free space, such as automation control systems, telemetry modules, compact LED lighting fixtures, and value actuators.

The ABCs of M12 Connectors: coding, pins, and locking systems

Introduced in 1985, the M12 connector has built a decades-long track record as one of the most reliable connectors for industrial applications. Once used primarily by automobile manufacturers, the M12 has become the industry standard in factory automation, autonomous robotics, communication, measurement and control, and many other applications.

Coding

On the plant floor or in the field, personnel need to be able to disconnect existing connectors for maintenance and install new connectors on newly laid cables quickly, especially where connections must remain dust- or water-tight. M12 connectors are easily installable and clearly coded to reduce the chance of accidental mis-mating.

M12 coding for signal and data transmission:

- A-coded for sensors, DC power

- B-coded for PROFIBUS

- D-coded for 100Mbit Ethernet and PROFINET

- X-coded for 10Gbit Ethernet

M12 coding for power supplies:

- S-Coded and K-Coded connectors are designed for AC power supplies up to 630V/16 A. Ideal power connector for applications including: AC motor and drives, motor control switches, and frequency inverters.

- T-Coded and L-Coded connectors are designed for DC power supplies up to 63V DC/16 A. Ideal power connector for low-voltage applications including: DC motor and drives, fieldbus Ethernet components, network devices, and LED lighting fixtures.

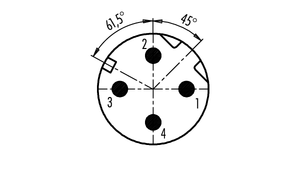

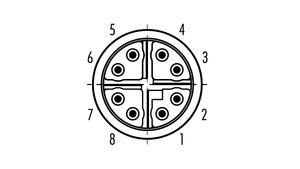

Pins

Pins M12 connectors are available with 3, 4, 5, 8, or 12 pins. The ideal pin count depends on the application. For example, most sensors and power applications use 3 or 4 pins, where PROFINET and Ethernet use 4 and 8 pins.

Locking systems

There are three basic types of locking systems on an M12 connector:

- Push-pull: Locks easily and securely with an audible click indicating that the proper connection has been established.

- Threaded coupling: A threaded nut on the plug is mated with a corresponding set of threads on the receptacle.

- Bayonet: An interconnect mating design that uses pins on the receptacle and ramps on the plug for quick-connect and disconnect coupling.

Additional M12 features and options

The connector choice for a specific application can be further customized by selecting options such as those below.

- Gender: male, female, male/female

- Termination style: crimp, screw, clamp, or IDT (Insulation Displacement Termination)

- Housing material: plastic, metal, or stainless steel

- Contact plating material: Au (gold), Sn (tin), CuSnZn (optalloy)

- Degree of protection: IP67, IP68, or IP69K

- Cable length

- Cable jacket: PUR or PVC

- Panel mounted or field attachable

- Rated voltage

- Rated current

M12 — one connector for everything

In industrial environments, to prevent mismatching, device connections require standardized, noninterchangeable connectors.

M12 A Coding

M12 A Coding

| Current | Voltage | Degree of protection | Number of contacts | Application |

|---|---|---|---|---|

Current 1.5 - 8 A | Voltage 30 - 250 VAC | Degree of protection IP67/IP68/IP69K | Number of contacts 3 - 12 | Application Power, Signal, CAN, CANopen, PROFIBUS PA, DeviceNet |

M12 B Coding

M12 B Coding

| Current | Voltage | Degree of protection | Number of contacts | Application |

|---|---|---|---|---|

Current 4 A | Voltage 60 - 250 VAC | Degree of protection IP67/IP68 | Number of contacts 4 - 5 | Application PROFIBUS DP |

M12 D Coding

M12 D Coding

| Current | Voltage | Degree of protection | Number of contacts | Application |

|---|---|---|---|---|

Current 4 A | Voltage 250 VAC | Degree of protection IP67 | Number of contacts 4 | Application Ethernet, EtherCAT, PROFINET, Sercos |

M12 X Coding

M12 X Coding

| Current | Voltage | Degree of protection | Number of contacts | Application |

|---|---|---|---|---|

Current 0.5 A | Voltage 50 VAC / 60 VCD | Degree of protection IP67 | Number of contacts 8 | Application Ethernet, PROFINET |

M12 S Coding

M12 S Coding

| Current | Voltage | Degree of protection | Number of contacts | Application |

|---|---|---|---|---|

Current 12 A | Voltage 630 VAC | Degree of protection IP67 | Number of contacts 3 + PE | Application Power supply |

M12 T Coding

M12 T Coding

| Current | Voltage | Degree of protection | Number of contacts | Application |

|---|---|---|---|---|

Current 12 A | Voltage 60 VDC | Degree of protection IP67 | Number of contacts 4 | Application Power supply |

M12 K Coding

M12 K Coding

| Current | Voltage | Degree of protection | Number of contacts | Application |

|---|---|---|---|---|

Current 12 A | Voltage 630 VAC | Degree of protection IP67 | Number of contacts 4 + PE | Application Power supply |

M12 L Coding

M12 L Coding

| Current | Voltage | Degree of protection | Number of contacts | Application |

|---|---|---|---|---|

Current 16 A | Voltage 63 VDC | Degree of protection IP67 | Number of contacts 4 - FE | Application Power supply, PROFINET, Recommended: Supply voltage |

The digitization of manufacturing is well underway, and picking up speed every day. Global tech analysts predict that more than 20 billion devices will be connected by 2020, supporting the Bain & Company forecast that the Industrial Internet of Things (IIoT) will be a $200 billion market by 2021.

In the simplest terms, the IIoT is real-time data connection, driven by processing and transmitting data at faster speeds, on progressively smarter and smaller machines. The ultimate value of the IIoT, however, goes beyond data collection and transmission. It encompasses the complete visibility and control of virtually all electromechanical factors in the manufacturing process, empowering companies to move beyond descriptive and diagnostic analysis to predictive intelligence and preventive action. Quantifiable benefits include the ability to identify disruptions such as product or process variance, and circumvent or redesign to avoid these issues. Plant operators can discover unused capacity, reduce maintenance costs and downtime, improve safety, and maximize overall equipment effectiveness (OEE) – the potential benefits of an IIoT-enabled plant are seemingly unlimited.

A comprehensive view of a manufacturing process or assembly line is accomplished by placing networked sensors on physical equipment to collect data. These sensors perform condition monitoring, analyzing constant input like temperature, vibration, or sound frequencies. This data is transmitted back to a central location or cloud where decision makers can access it. This process requires reliable high-speed connections, often in environments that include dust, noise, temperature changes, and vibration; in industries such as food and beverage, there is the additional challenge of frequent washdowns. Connectors act as the vital link between the cables carrying data and the devices that record and communicate information. The demand for faster data transmissions that can accommodate visuals has driven the development of connectors able to support the gigabit data requirements for the latest sensors. To add to the complexity, machines are getting smaller, putting pressure on component makers to deliver greater speed, power, and capacity in an ever-shrinking footprint.

M12 technology continues to evolve

Machine designers and OEMs are incorporating M12 connectors into new machines, as well as updating existing infrastructure. With backwards compatibility, replacing older and less robust technology like RJ45 connectors is relatively simple and cost effective. Manufacturers of M12 connectors continue to innovate, adding new features to meet the quickly changing needs of the robotics, automation, food and beverage, alternative energy, and cellular communication industries. Positionable, lockable, field-wireable connectors, capable of transmitting impressive amounts of data and power, ensure that the M12 will continue to be an essential component of Industry 4.0 and beyond.

Sources

Bain & Company. Beyond Proofs of Concept: Scaling the Industrial IoT. Web. Jan. 30, 2019.

Columbus, Lewis. 2018 Roundup of Internet of Things Forecasts and Market Estimates. Forbes. Web. Dec. 13, 2018.

Deloitte Digital/WIRED Brand Lab. Industrial IoT: How Connected Things Are Changing Manufacturing. Web. Accessed May 20, 2019.

Electronics Sourcing Online. Smart sourcing for industrial IoT. Web. June 15, 2018.

Fenical, Gary. The Basic Principles of Shielding. In Compliance. Web. Mar. 1, 2014.

Schweiz, Laura. Ethernet Connectors Evolve to Meet New Demands. Machine Design. Web. Mar. 14, 2016.

Thomas. Measuring EMI Shielding Effectiveness. Thomasnet.com. Web. Accessed May18, 2019.